Improving Reliability of Results for Airgap Modeling of Electric Motors (3D)

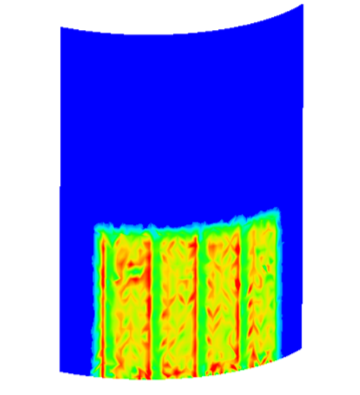

When there is motion in the simulation, the mesh on the interface of the moving and stationary domains can become non-conformal (i.e., the nodes at the two sides of the interface are not in the same positions). This requires some interpolation/mapping technique to map the fields from one side to the other. Depending on the method used for this mapping, hot spots of the field on the interface can occur due to numerical error as shown in the figure below.

Some typical results of interest around electric machine simulation are considerably sensitive to this numerical error at the interface between moving and stationary domains. One example for such a result is the cogging torque of permanent-magnet synchronous machines. Hot spots of the magnetic field in the interface could lead to the wrong result for cogging torque.

The Continuum Air [3D] beta feature can be used to improve the smoothness and accuracy of the field solution so that the simulation can be more robust and accurate.

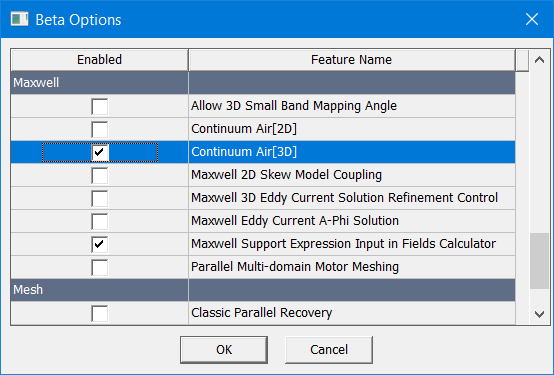

To turn on this feature:

- Open the Tools > Options > General Options window.

- Click the Beta Options button.

- Scroll down to the Maxwell options, and select Continuum Air [3D].

- Click OK in the Beta Options window and in the General Options window.

- Click Yes to restart Ansys Electronics Desktop to activate the feature.

Other result quantities of interest that may show considerable improvement in accuracy with this feature include NVH-forces and core losses at the stator (as considerable core loss density occurs at the stator tooth tips, in the vicinity of the interface).

Supported functions for this beta feature include

- All Excitation Winding Types: Current / Voltage / External

- Motion Type: Rotation

- Full / Partial model

- TDM

The following functions are not supported in this release:

- Partial mesh for full model

- Motion Type: Translation / multi-motion

- Component of core loss based on normal flux

- Anisotropic nonlinear material

- Anti z-direction dependent/independent boundaries

Related Topics

Meshing Recommendations for 3D Transient Applications with Motion